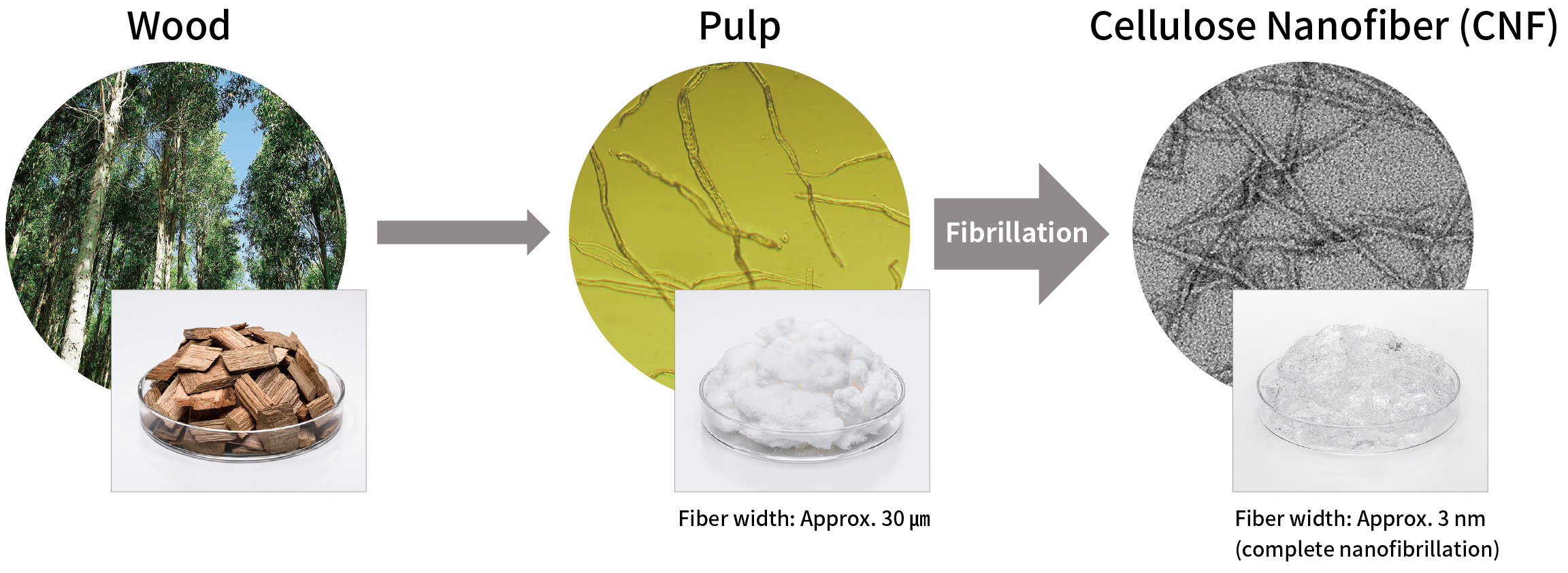

Cellulose Nanofiber (CNF) is produced by fibrillating wood fibers (pulp) at the nanometer (one-millionth of a millimeter) level (hereafter, "nanofibrillation").

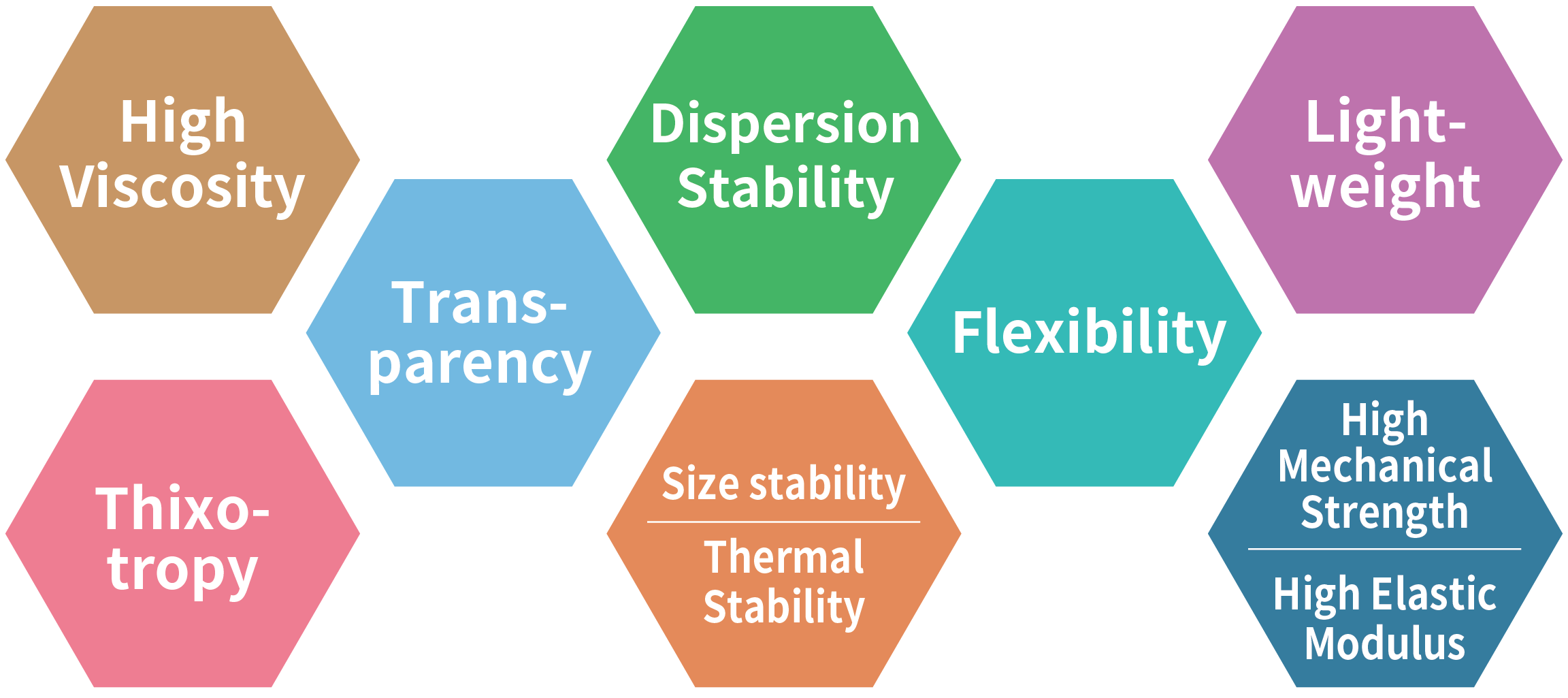

CNF is an excellent material that is transparent, light weight, tough, deformation resistant, and has a high viscosity increasing effect that is expected to have applications in many different fields, such as in the areas of plastics and carbon black, and it is expected that it will replace existing materials and add new functions to products.

Oji's Cellulose Nanofiber

Cellulose Nanofiber (CNF) is a biomass material that is produced by fibrillating wood fibers, a raw material of paper, at the nanometer (nm) level.

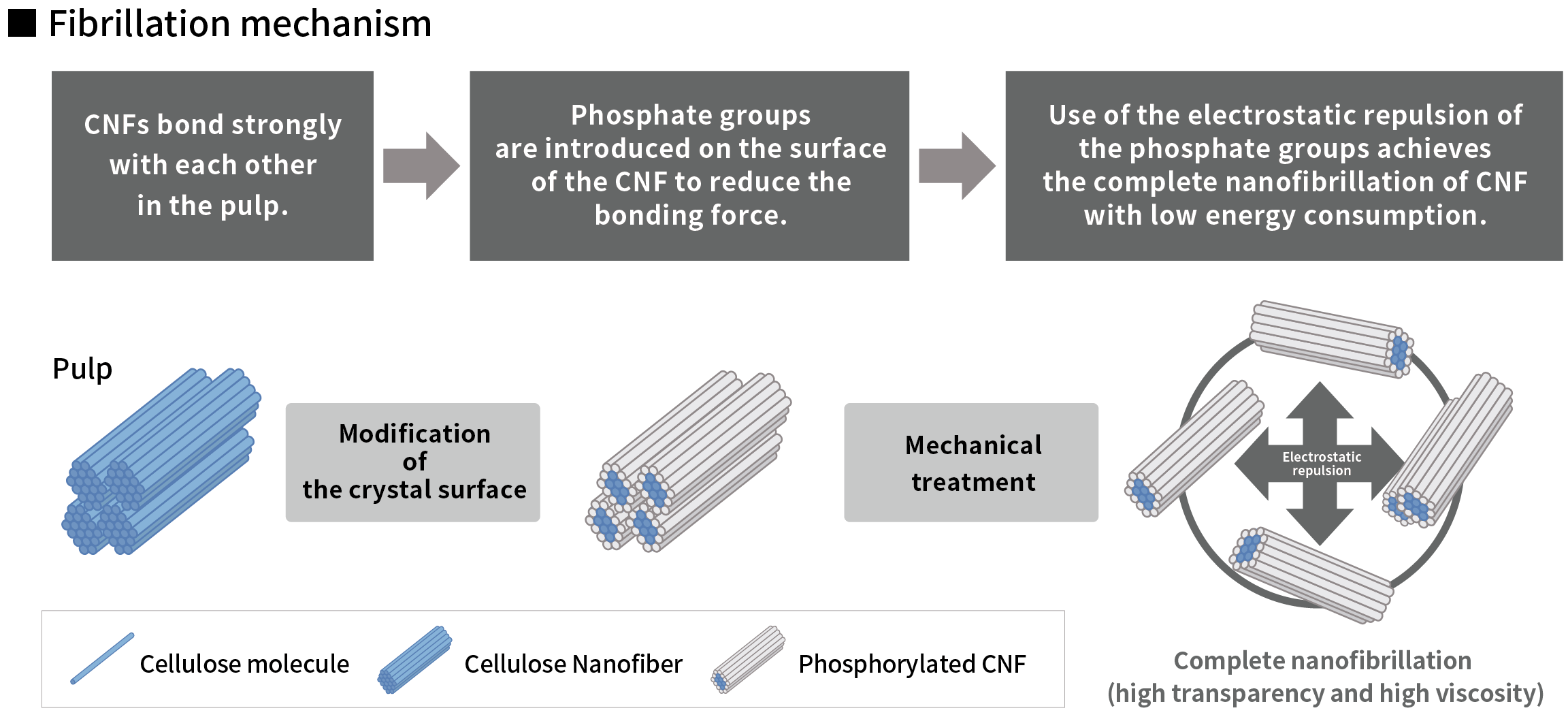

Oji's Phosphorylated CNF

The Oji Group uses the phosphorylation method to effectively reduce the energy consumed during the fibrillation process in manufacturing. This has enabled us to produce CNF products that are higher quality (high transparency, high viscosity and thixotropy) with increased efficiency. In 2017, a pilot facility producing CNF using this method started operating at the Tomioka Mill of Oji Paper Co., Ltd.

Presently, we manufacture a wide variety of CNF products, including the AUROVISCO transparent CNF slurry and a coarse CNF slurry. We are proactively working to provide samples and broaden the range of applications of CNF to commercialize it.

Cellulose Product Line

We are working to develop products to effectively use cellulose materials, from CNF to pulp, in response to changes in society and customers' needs.

- CNF Slurry

- Hydrophobic CNF

- CNF Sheet

- CNF and Natural Rubber Masterbatch

- Cellulose Resin Composite Pellets

AUROVISCO CNF Slurry

AUROVISCO is a water dispersion of super-fibrillated wood fiber cellulose nanofibers (CNFs) with fiber width of approx. 3 nm. With unique properties such as extremely high viscosity and thixotropy, it is expected that AUROVISCO will be used in a wide range of fields. Another feature of AUROVISCO is its high transparency, which makes it possible to add it to materials where aesthetic qualities and transparency are requirements.

- High transparency

- High viscosity

- High thixotropy

- pH stability and salt resistance

-

High-viscosity product (solid content: up to 2 wt%, pH: 8 to 10)

The addition of even a small amount of AUROVISCO highly improves viscosity because it is more viscous than conventional natural thickeners. - It is also possible to consider customization for low-viscosity products and high-concentration products.

- A hydrophobic CNF slurry (development article) is also available. We are ready to study its dispersion using organic solvents upon request.

Features and examples of use

- High viscosity ensured using small amounts, compositional homogeneity, and high thixotropy that prevents dripping — Paints, inks, and chemical products

- High viscosity without stickiness and naturally derived — Cosmetics and beauty care products

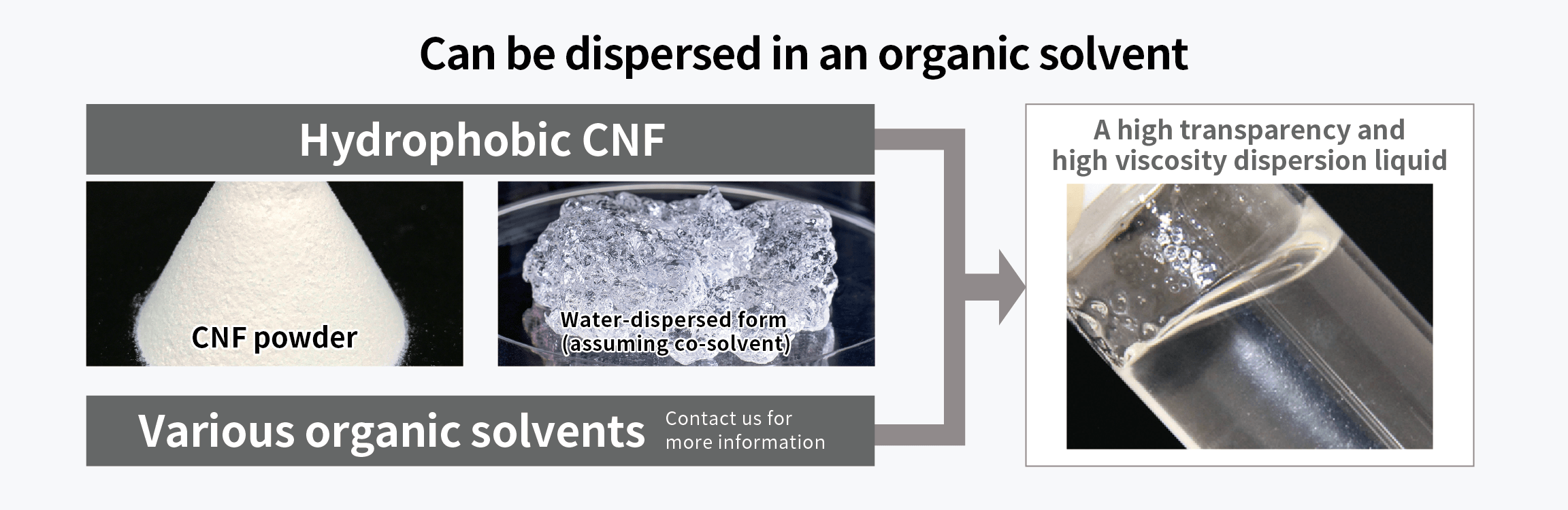

Hydrophobic CNF Powder — Development article

Featuring strong hydrophilicity, CNF is incompatible with organic solvents and resins.

The Oji Group has developed a hydrophobic CNF powder using our proprietary technology to reduce the water content of CNF and increase its solid content up to 90 wt%.

This led us to succeed in dispersing CNF in various organic solvents, which had been a difficult process. The high transparency and viscosity of this dispersion liquid is equal to water dispersions. Therefore, it is expected that this dispersion can be used to improve) elastic modulus in combination with resins, to improve the rheology of paints and inks, to synthesize various organic solvents, and in other applications.

- Hydrophobicity

- Compatibility with organic solvents

- High transparency

- High viscosity

- High strength

Features and examples of use

- Dispersion in organic solvents/improvement of elastic modulus and viscosity — Solvents for electronic substrates, electronics, etc.

AUROVEIL CNF Sheet

At the Oji Group, we have developed the world's first technology for manufacturing continuous transparent CNF sheets using completely nanofibrillated CNF with a fiber width of 3 nm.

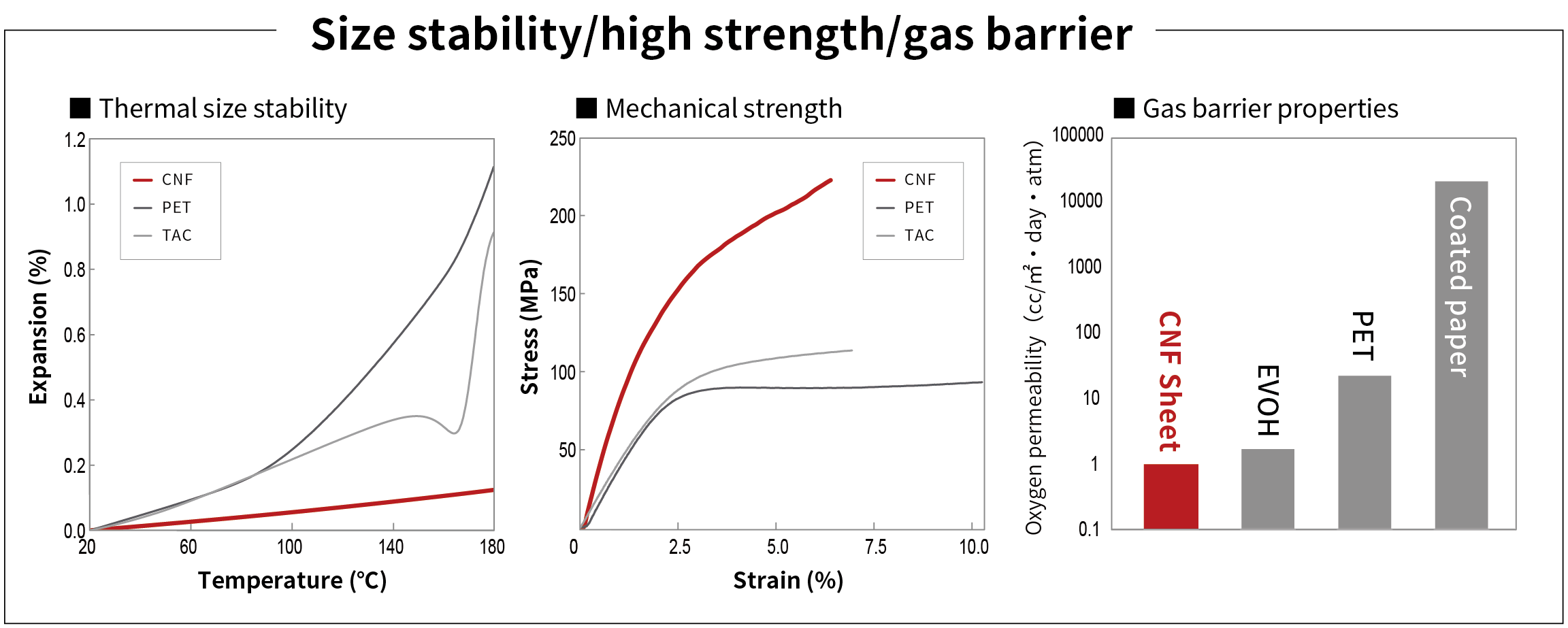

The AUROVEIL transparent CNF sheet boasts high transparency and high size stability equivalent to glass, despite being a woody biomass raw material. Further, AUROVEIL also features high strength, a high elastic modulus, and superior flexibility.

- High transparency

- Low expansion

- High strength

- Flexibility

- Gas barrier

Use of the CNF sheet in combination with another material enables users to add the properties of the CNF sheet to products to further enhance their functions.

Features and examples of use

- Transparent sustainable material, high strength, and high performance — Lifestyle-related products

- Sustainable material, high thermal resistance, and size stability — Electronics-related products

- Weight reduction of transparent components and environmental friendliness — Automotive parts and digital signage

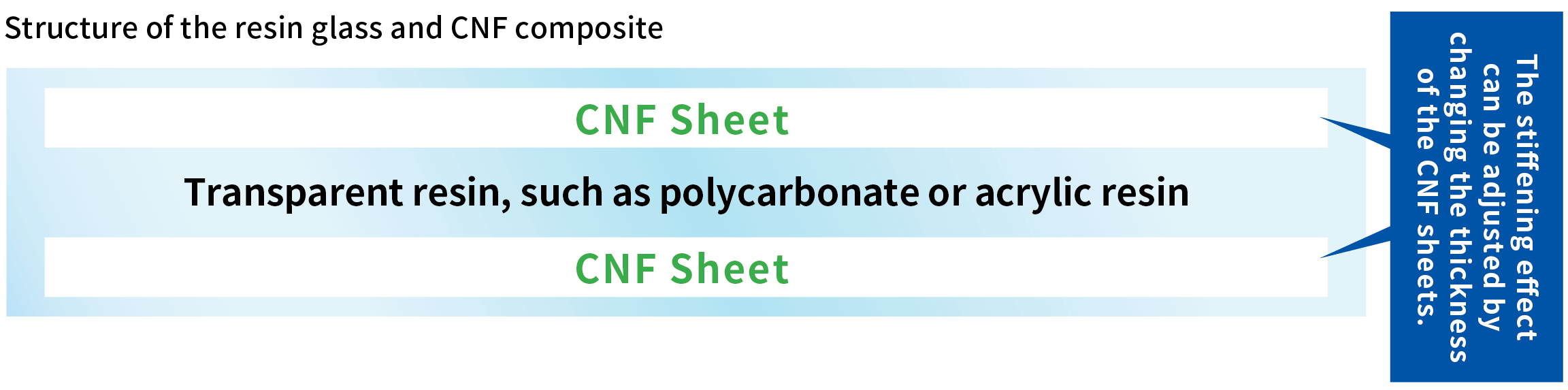

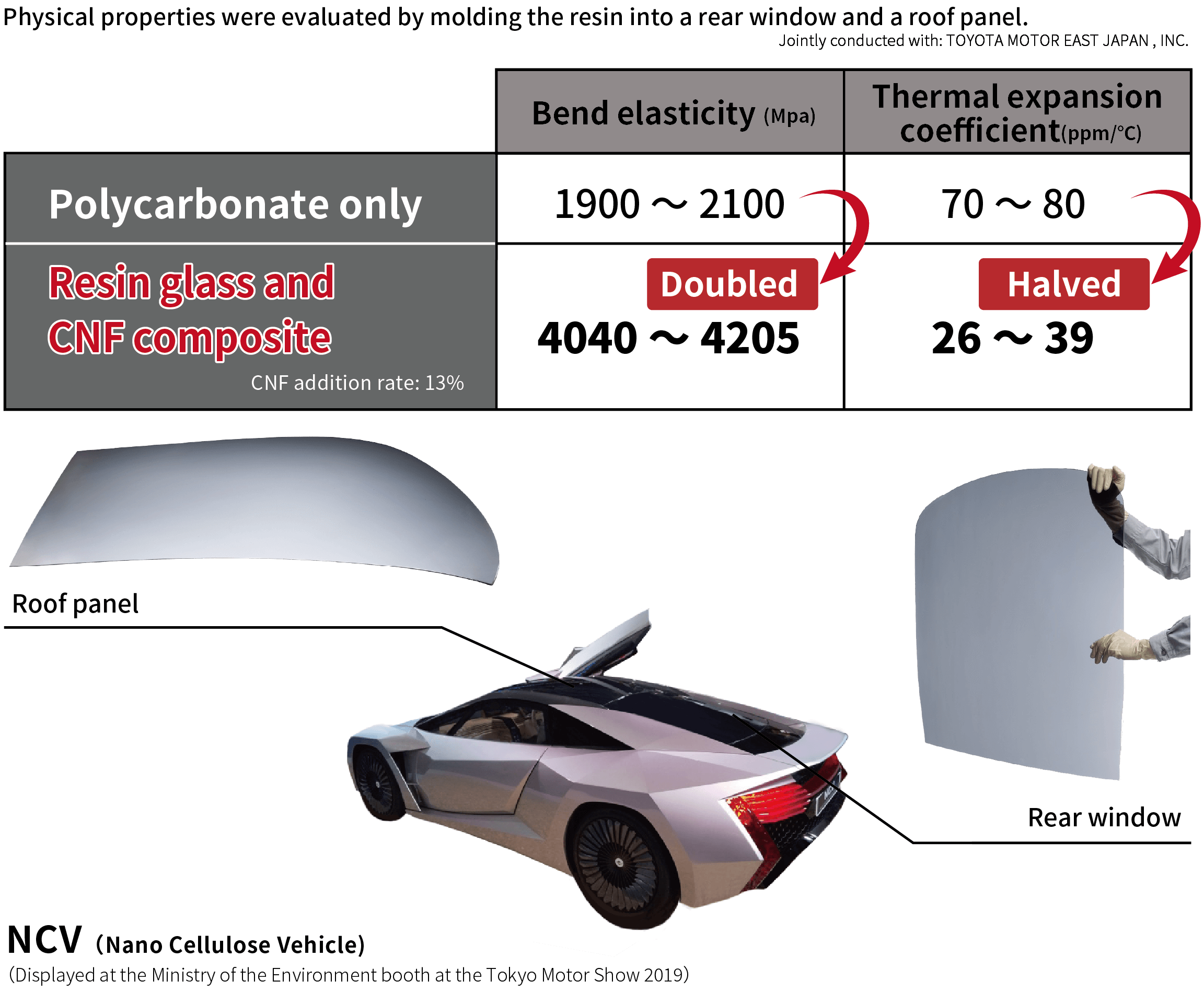

Example composite (1): Resin glass and CNF composite

We have established a technology for combining cellulose nanofiber sheet (AUROVEIL) with resins such as polycarbonate and acrylic resins. They are environmentally friendly composite materials, which enable users to reduce their use of petrochemical and plastic materials while taking advantage of the features of each material.

[Examination]

There are issues in the melting and mixing of CNF and transparent resins, such as the degradation of CNF caused by heat or defective dispersion. To respond to these issues, we combined CNF sheets with transparent resins by gluing CNF sheet which is transparent, mechanically strong, and has size stability, to the resin.

[Results]

The higher elastic modulus and lower thermal expansion rate of the transparent resin were achieved while maintaining its transparency, just by gluing the CNF sheet to the resin. A durability test (90 °C for 720 hours) showed that the color difference (⊿E) was 3 or lower. In addition, the resin did not break during a DuPont impact test (conducted using a 1 kg* weight dropped from a height of 50 cm at room temperature).

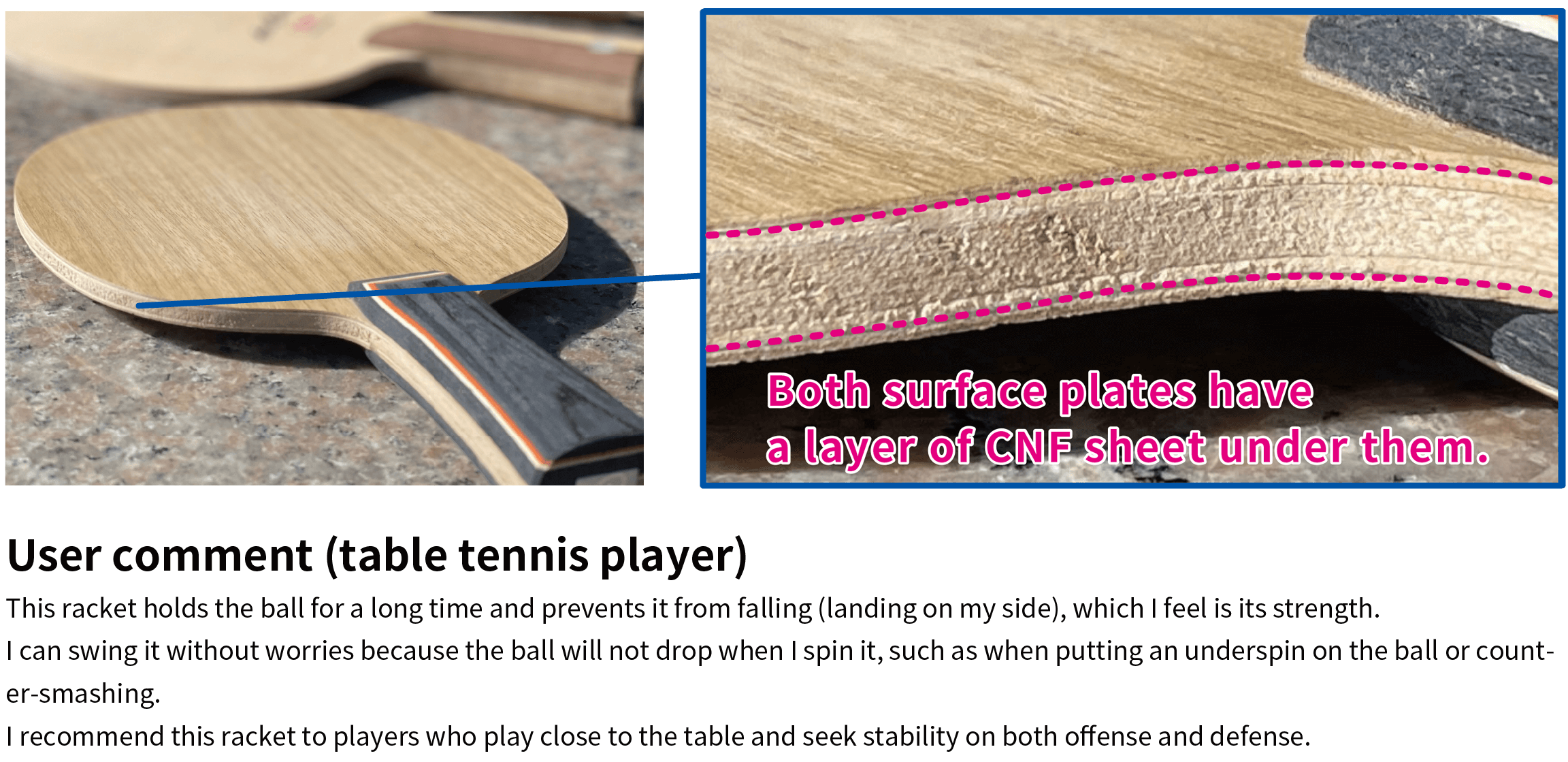

Example composite (2): Wood and CNF composite

A table tennis racket with a new feeling of hitting a ball

A table tennis racket featuring a new level of rebound strength and elasticity was developed using a combination of our CNF sheet and wood as the base material of the racket.

The sheet design can be optimized to suit the needs of the user

Our proprietary technology for making CNF sheet, which enables us to control its thickness, has made it possible to design sports equipment that is both light weight and transmits the feeling of hitting the ball or other object (including rebound strength, elasticity, and strength).

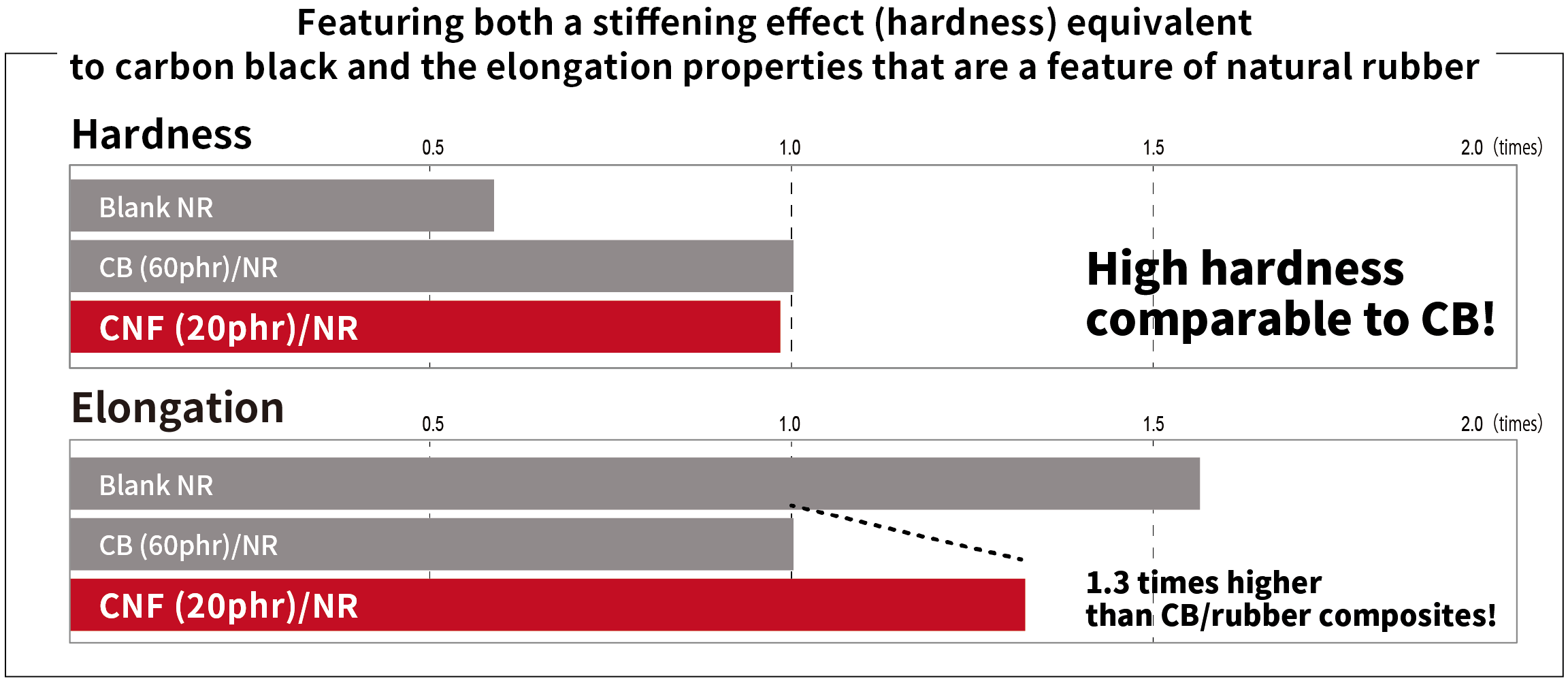

Natural Rubber and CNF: Rubber-containing Masterbatch

This is rubber-containing masterbatch created using a combination of our unique phosphorylated CNF and natural rubber. The addition of even a small amount of the masterbatch improves elastic modulus and imparts superior strength and elongation properties. It is therefore an environmentally friendly material that is expected to reduce the use of carbon black (CB), which is derived from petroleum.

- Biomass materials

- Functional enhancement

- Energy efficiency and durability

- Aesthetic quality

Features and examples of use

- Increase in biomass content ⇒ Environmentally friendly concept rubber products such as tires

- High strength, excellent elongation ⇒ General rubber products with CB (carbon black) and silica

- Energy saving, weight reduction ⇒ Tires, automotive rubber products, shoe soles

- Design ⇒ Colored rubber products