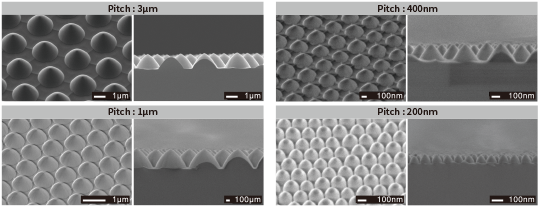

Nano dot array technology originated from Oji group enables fine fabrication ranging from hundreds nm to microns in pitch at the surface. Wide variety of applications has been presented for the customers such as optics, analytical chemistry, and life science/medical fields.

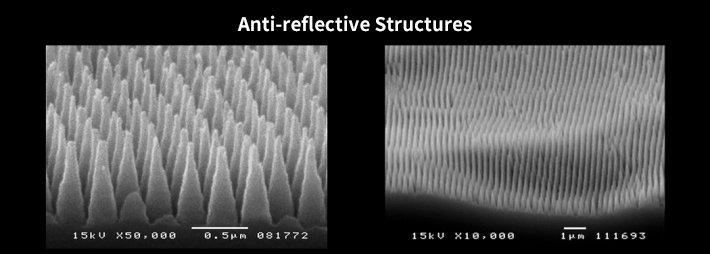

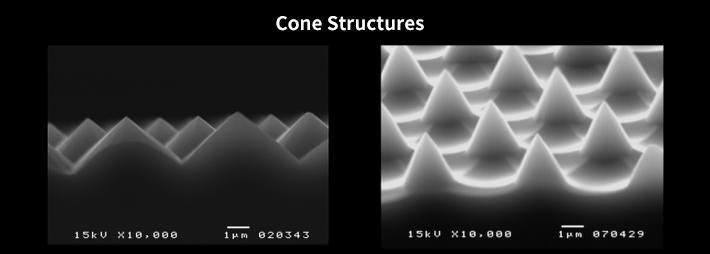

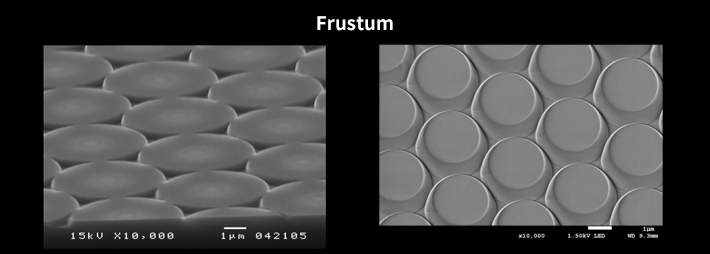

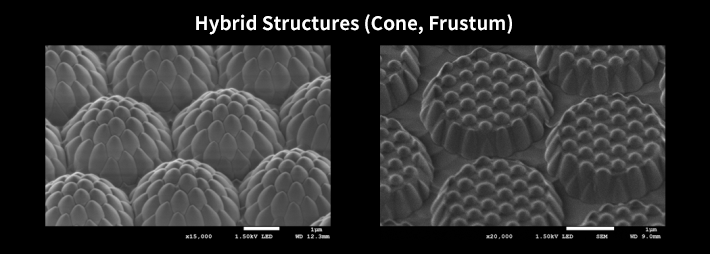

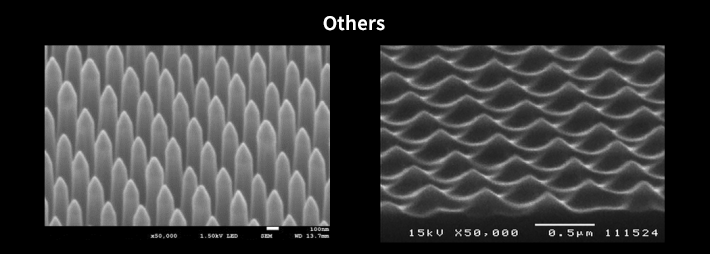

Various nano structures

Nano dot structures with various shape and size are fabricated. Customizations are available.

Various applications for wide technical fields

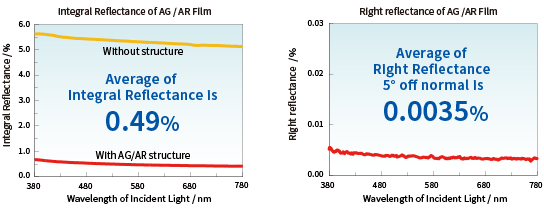

- Specular Anti-reflective structures

- Anti-glare / Anti-reflective structures

- Sapphire Substrates with Fine Structure

- Plasmonic Device

- Cell culture substrates for controlled cell orientation

- High sensitive SERS* substrates for Raman Spectroscopy

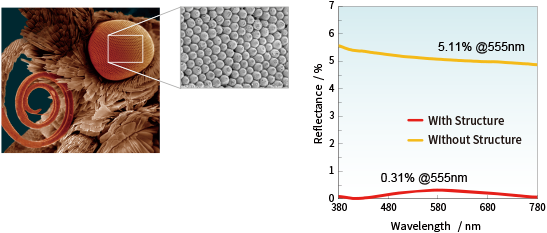

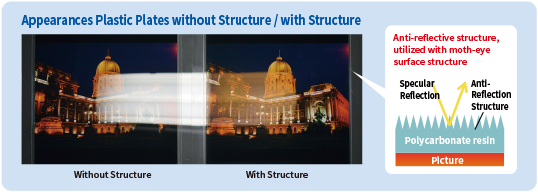

Application of Nano Dot Array 1, Specular anti-reflective structures (anti-reflection and improvement of transmittance for flat surface)

A film with moth-eye surface structure (Upper Fig. : nano sized dot-type structure) decreases reflectance (increases transmittance) of light.

Films or plastic moldings with anti-reflective structure at the surface are available.

- Application

- Mirrored optical pats requiring low-reflectance and high-transmittance.

- Materials

-

(Direct fabrication)Silicon, Quarts glass etc.

(Plastic molding)Acrylic resin, Poly styrene, Poly carbonate, Cycloolefin resin, etc.

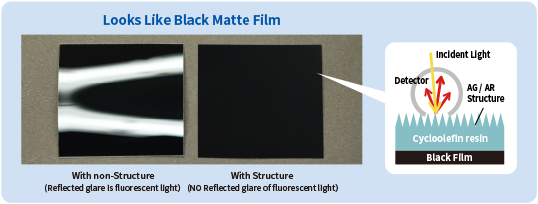

Application of Nano Dot Array 2, Anti-glare / Anti-reflective structures (anti-reflection of uneven surface)

- Application

- Surface requiring low reflectance, e. g. inside of optical enclosure for reduction of stray light. (inside of camera and optical inspection instruments)

- Materials

- (Plastic molding)Acrylic resin, Poly styrene, Poly carbonate, Cyclo olefin resin, etc.

Application of Nano Dot Array 3, Sapphire Substrates with Fine Structure

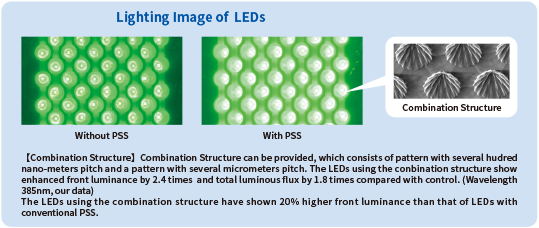

Patterned sapphire substrate (PSS)* is available, which enables high light extraction efficiency. Fine fabrication is possible at the surface of the growth face of semiconductor crystal and the light extraction face of flip-chip type (opposite face of the growth face).

* PSS:Patterned Sapphire Substrate

- Application

- Control of epitaxial growth on optical elements such as LEDs, Enhancement of light extraction efficiency by outcoupling effect, etc.

- Materials

- (Direct fabrication) Sapphire, Silicon carbide, Silicon, Quartz Glass, Gallium Nitride, etc.

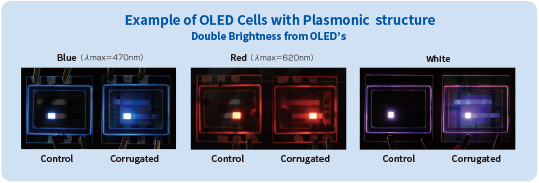

Application of Nano Dot Array 4, Plasmonic Device

Device using surface plasmons

Fine structures are available which improve light extraction efficiency of OLEDs and enhance photoelectric conversion efficiency of Organic thin-film solar cells.

- Application

- Improvement of brightness and reduction of power consumption of OLEDs, Enhancement of photo electric conversion efficiency of Organic thin-film solar cells, etc.

- Materials

- Quartz Glass, Ordinary glass, Silicon, Silicon Carbide, Sapphire, Plastic films, etc.

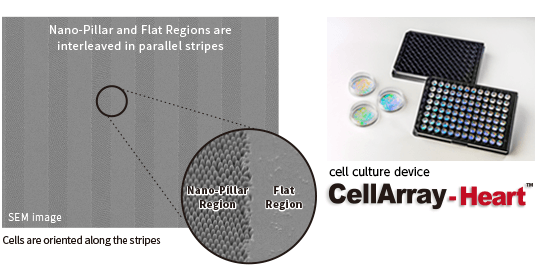

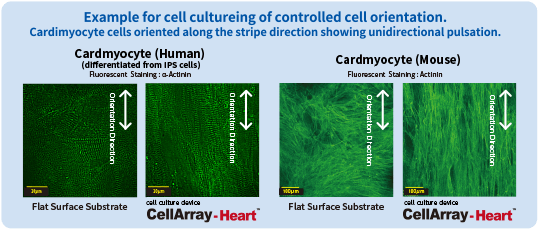

Application of Nano Dot Array 5, Cell culture substrates for controlled cell orientation

Cell-sheet with controlled cell orientation, exhibit bioactivity similar to that in vivo, hence it may be possible to use the sheet for bio assays and regenerative medicines. The newly–developed cell culture substrates have nano-pillar and flat regions interleaved in parallel stripes, and by means of the substrates, orientation of myoblast and carbiomyocyte cells have been confirmed.

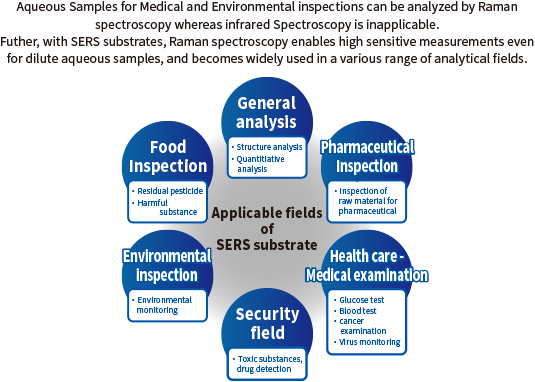

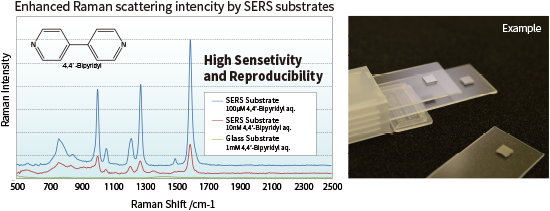

Application of Nano Dot Array 6, High sensitive SERS* substrates for Raman Spectroscopy

When light enters metal nanostructured surfaces, electromagnetic filed is amplified by surface plasmon resonance. In this field, Raman intensity of analyte is significantly enhanced (Surface Enhanced Raman Scattering), and it is used for high sensitive Raman spectroscopy analysis.

*SERS (Surface Enhanced Raman Scattering)

Characteristics of our SERS substrates.

SERS substrates with Au and Ag fine structures are available. Encouraged excitation wavelengths are 780nm for Au-SERS and 532nm for Ag-SERS substrates. For both types of SERS substrates, expiry date is about 3 months after shipment.

- Application

-

Micro analysis such as environmental and pharmacentical inspection, Raw materials analysis, etc.

Specifically suitable for aqueous samples. - Materials

- Au or Ag fine structures on silicon or glass substrates.