Oji Group's Innovation for a Sustainable Future

The Oji Group is pushing forward with the development of sustainable materials and the creation of new businesses using wood resources. We are engaged in these efforts based on the foundation of our abundant forest resources and our core technologies, which we have cultivated over more than 150 years of forestation and paper manufacturing.

We are simultaneously developing sustainable packaging businesses, which we aim to expand early as a short- to medium-term initiative, and forest biomass business, which are the core of our medium- to long-term businesses. Through these efforts, we are contributing to the creation of innovative value and the expansion of our business domains for sustainable growth.

Sustainable Packaging

Environmentally friendly paper packages promoting de-plasticization

We provide liquid paper cartons and environmentally friendly packaging materials, which help reduce CO2 emissions and the consumption of plastics derived from fossil resources, in accordance with brand owners' needs.

By investing in overseas companies and M&A activities, we are upgrading and expanding our paper packaging materials to meet the de-plasticization-related demand. These materials include liquid paper cartons featuring high recyclability, soft packaging materials made from barrier paper that can also be used for food packaging, and high-quality pulp-mold packages featuring strength and aesthetic qualities.

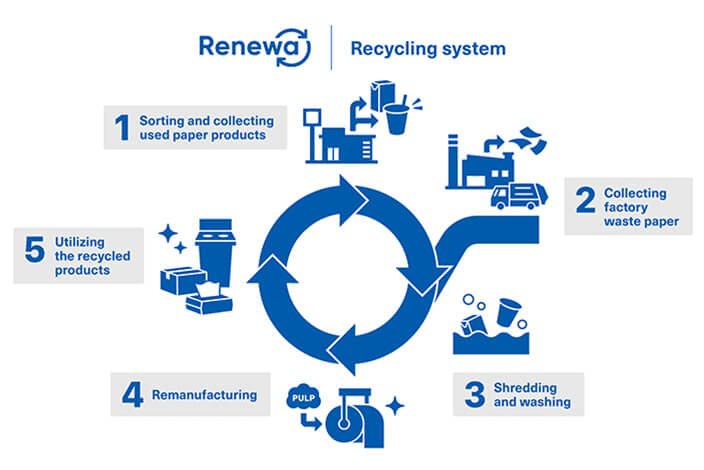

Establishment of the Collaborative Recycling System “Renewa”

Oji Group, through its recycling brand “Renewa”, is promoting the initiatives to make previously hard-to-recycle materials renewable to contribute to therealization of a sustainable society.

For example, beverage paper containers such as paper cups and aseptic carton packages are typically excluded from conventional paper recycling systems due to plastic lamination and after-use contamination, resulting in mostly being discarded.

To address this issue, Oji Group has developed a proprietary system that uses pre-treatment processes such as shredding and washing, along with specialized equipment, to remove contaminants and laminated layers, enabling the recovery of paper fibers (pulp). The recycled pulp is then recycled into products such as cardboard and hand towels, contributing to effective resource utilization.

Moving forward, Oji Group aims to expand the circle of resource circulation through ongoing technological development and collaboration across industries.

Acquisition of Walki: One of Europe's leading environmentally friendly packaging company

To build a foundation for our packaging business, we acquired Walki Holding Oy, a Finnish company engaged in the processing and manufacturing of sustainable packaging materials in April 2024.

Walki's mainstay core products are paper-based environmentally friendly packaging materials featuring boththat combine recyclability and barrier properties. The company is distinguished by its high profitable in the European market, where environmental regulations are becoming increasingly stringent.The company boasts high profitability in Europe, a market where environmental regulations are increasingly strict.

We will further strengthen the Group’s business foundation as a global supplier to meet the worldwide demand for conversion to sustainable packaging materials.

Forest Biomass Business

Development of biomanufacturing technologies using wood resources as raw materials

We are proceeding with the development of biomanufacturing technologies that use wood resources as raw materials.

In particular, we are focused on sugar solutions, which are a key substance for various types of biomanufacturing processes,*1 ethanol that can be used to manufacture SAF*2 and other chemicals, and polylactic acid which is a representative biomass plastic. To establish technologies for manufacturing these substances, we will accelerate initiatives for their social implementation, including the installation of a pilot plant for manufacturing sugar solutions and ethanol and the Biomanufacturing Ecosystem Construction Project Using Wood and Other Under-Utilized Resources, which was selected as a NEDO project.

- *1 Manufacturing processes with the goal of eliminating dependence on petroleum resources. A feature of these processes is their use of biomass-derived sugar as a raw material and microbes with an enhanced ability to produce functional materials (smart cells)

- *2 Sustainable aviation fuel: Fuel seen as a last resort for the decarbonization of the aviation industry

Utilizing cellulose (CNF) in response to changes in society

Cellulose Nanofiber (CNF) and cellulose products from Oji Holdings are produced by fibrillating wood fibers (pulp).

The fiber fibrillating process enables them to have outstanding functionality despite being biomass materials, including high transparency, high viscosity and high strength. Because of these properties, they are expected to have many applications in a wide range of industrial fields, including automobiles and other transportation equipment, electronics and chemical products.

Information about CNF and cellulose products, including their properties and example applications, are available on the product information page.

Advanced semiconductor photoresist made from biomass raw materials

This is a PFAS-free, environmentally friendly advanced semiconductor photoresist made from biomass raw materials.

We have used proprietary technology maximizing the power of biomass for this product. Having confirmed its basic performance, we are optimizing the product for semiconductor device manufacturers.

Stable supply of licorice, a medicinal plant, through large-scale cultivation

Japan is dependent on imports for much of the licorice consumed domestically. This has also led to resource depletion and environmental conservation issues associated with the harvesting of wild licorice.

In addition, there is the risk that export restrictions will be implemented or other problems will occur. Therefore, there is demand for domestically produced licorice. We cultivate licorice in Japan to guarantee high-level traceability and be ready to support safe, reliable and sustainable businesses.

We process our licorice as requested by customers, thereby expanding its use into the fields of pharmaceuticals, cosmetics, and food products.

Medicinal products derived from wood

Oji Pharma was established in 2020 for R&D and commercialization of medicinal products made from sulfated hemicellulose. This substance is obtained from hemicellulose, a by-product of pulp production.

Sulfated hemicellulose from Oji Pharma is unique because it is derived from wood, in addition to its anti-inflammatory and anti-coagulant properties.

Possessing the benefits of safety, reliability, and stable supply that are unique to wood-derived products, sulfated hemicellulose has the potential to replace animal-derived pharmaceutical products such as heparin.

About the Innovation Promotion Division

Major productization and commercialization initiatives

- Cellulose Nanofiber Cellulose Nanofiber is produced by fibrillating wood fibers (pulp) at the nanometer (one-millionth of a millimeter) scale (hereafter, "nanofibrillation").

- Nano Dot Array Oji Group's proprietary nano dot array technology makes it possible to create surface nanostructures with a pitch ranging from hundreds of nanometers to microns.