- Policy

- Structure

- Targets and Achievements

- Initiatives

- Status of Reduction and Effective Use of Waste

- Actions for a Plastic-free Society

- Data

Policy

The Oji Group is implementing initiatives to reduce waste and ensure proper management, and contribute to the transition to a circular economy. The Oji Group sets targets to reduce waste generation and the amount of waste disposed of by landfill, and is taking actions to achieve the target.

Structure

Targets and Achievements

To achieve waste reduction, the Oji Group set a target for improving its effective waste utilization rate*1.

Improving this rate requires reducing the volume of waste sent to landfill. This target is achieved by (1) recycling waste that would otherwise be landfilled and (2) reducing the generation of waste destined for landfill.

In the Environmental Action Program 2030, the Oji Group set a target to achieve an effective waste utilization rate of at least 99% in Japan and 95% overseas by FY2030.

In the Environmental Action Program 2040, formulated in May 2025, the Oji Group set a target to maintain and improve an effective waste utilization rate of 99% or higher in Japan and 95% or higher overseas by FY2040.

- *1 Effective waste utilization rate = (volume of waste generated − volume of landfill waste) ÷ volume of waste generated x 100

| FY2018 | FY2019 | FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | FY2030 (Terget) |

|

|---|---|---|---|---|---|---|---|---|

| Japan | 98.3% | 98.4% | 98.8% | 99.1% | 99.4% | 99.0% | 99.4% | 99.0% or more |

| Overseas | 89.6% | 88.5% | 89.4% | 89.1% | 83.4% | 86.4% | 90.2% | 95.0%or more |

Initiatives

The Oji Group is working to reduce waste generation and final disposal (landfill) volumes by setting targets for an effective waste utilization rate of 99% in Japan and 95% or higher overseas (final disposal rates of 1% in Japan and less than 5% overseas).

We are contributing to the transition to a circular economy and reducing our impact on the environment by minimizing the waste generated in our manufacturing processes, and by properly treating, recycling and effectively utilizing waste.

To achieve the targets, each business site ensures proper waste management and provides education to employees on waste segregation.

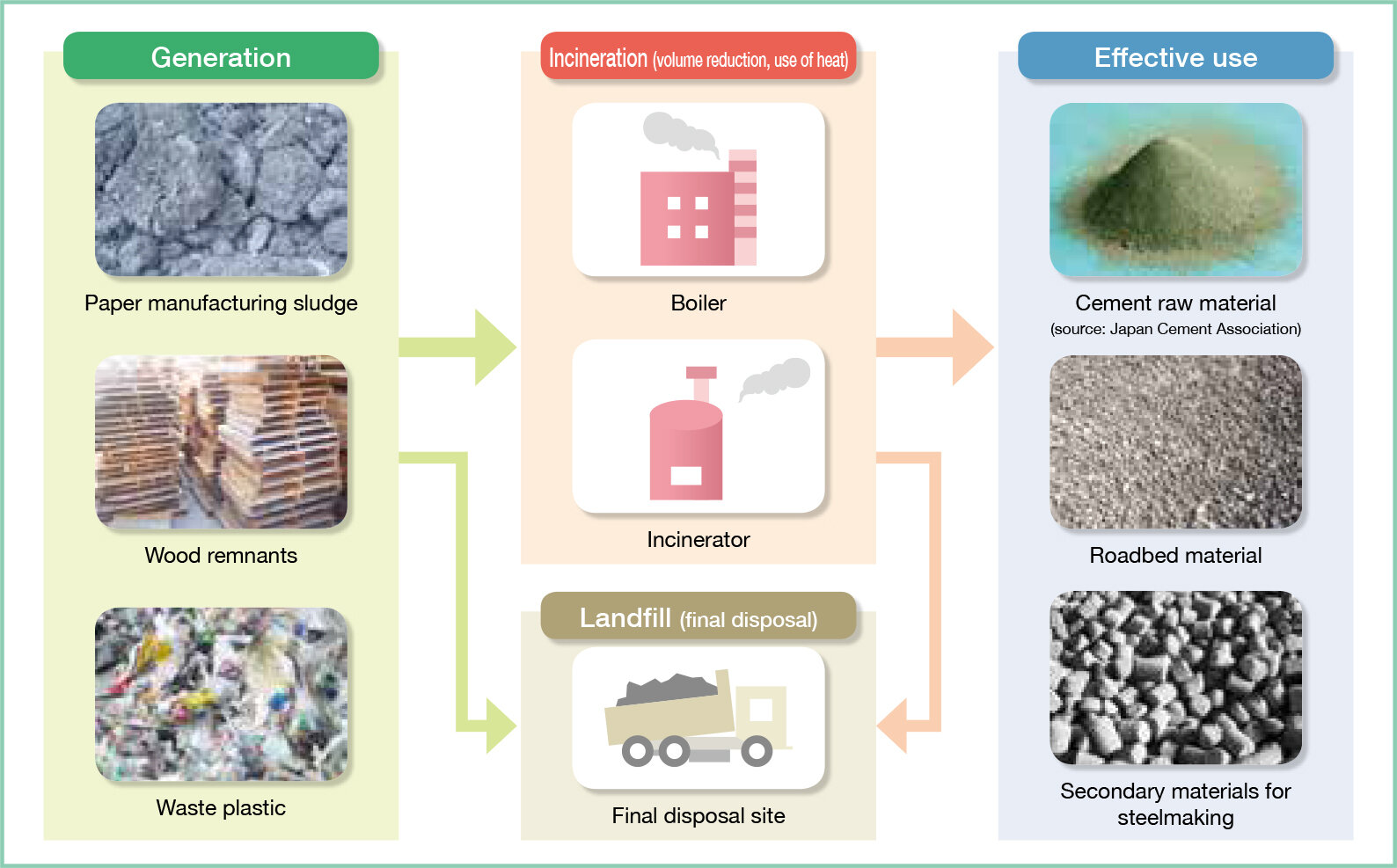

Status of Reduction and Effective Use of Waste

Waste includes paper manufacturing sludge generated in the manufacturing process, wood waste during processing and ash during fuel combustion. Any wastes are treated to make them harmless and they are used effectively.

In Japan, ash is used primarily as a raw material in cement and roadbed materials. Overseas, paper manufacturing sludge is used as fertilizer and for other applications.

We continuously work to reduce the amount of waste generated and to expand our effective utilization of it.

The effective waste utilization rate*2 in FY2024 was 99.4% in Japan and 90.2% overseas.

We will continue to work to enable the recovery and reuse of raw materials from the water used in the manufacturing process and the effective use of the ash generated in the combustion of fuels to obtain electricity and heat used in the production process for roadbed materials, etc., to reduce our environmental impact.

- *2 Effective waste utilization rate = (amount of waste generated − amount of landfill waste) ÷ amount of waste generated × 100

Collaboration with Industry Associations and Other Companies

The Oji Group participates in the Environmental Action Plan (Waste Management) of the Japan Paper Association, of which it is a member. To achieve the industry association target for reducing landfill disposal volumes, the Oji Group is advancing its own initiatives.

Actions for a Plastic-free Society

In the field of packaging materials, one of the Group's core businesses, we have contributed to the reduction of plastics in society as a whole by reducing plastic usage by approximately 3,000 tons in FY2023 through the replacement of plastic products with sustainable packaging.

We will expanded sales of sustainable packaging by approximately 5,000 tons by FY2030 and contribute to the transition to a plastic-free society and a circular economy.

Within the Oji Group, Oji Nepia is transitioning to plastic-free packaging materials.

More than 90% of the waste plastic discharged from the Oji Group is derived from plastic mixed with recovered paper, the raw material for paper and paperboard.

Each of our manufacturing sites actively ensures effective utilization of waste plastics. In particular, sites classified as large plastic waste generators*3 have accelerated their efforts and in FY 2024, approximately 98% of this waste was recycled (including thermal recycling). The Oji Group sets the target for large waste generators to achieve a 100% recycling rate by FY2030.

- ※3 Total for 9 Oji Group companies in Japan subject to the Act on Promotion of Resource Circulation for Plastics (Oji Paper Co., Ltd., Oji Materia Co., Ltd., Oji F-Tex Co., Ltd., Oji Nepia Co., Ltd., Oji Imaging Media Co., Ltd., Oji Container Co., Ltd., Morishigyo Co., Ltd., Oji Tac Co., Ltd., and New Tac Kasei Co., Ltd.)

1. Expansion of sales of sustainable packaging

To recycle for the future, we reduce the amount of plastic used by society as a whole by facilitating the expansion of sales of renewable eco-friendly products, such as the transition from plastic packaging to paper.

2. Results for FY2024

In FY2024, 65,572 tons of waste plastic were generated from manufacturing sites of Oji Group's nine large plastic waste generators. Approximately 98%, or 64,561 tons, was recycled (including thermal recycling) and 1,009 tons of waste plastic remained unrecycled.

Table:FY2024 Targets, Waste Plastic Generation, Recycled amounts of Nine Large Plastic waste Generators, and Sustainable Package4 Sales Performance

| FY2021 | FY2022 | FY2023 | FY2024 | FY2030 (Target) |

|

|---|---|---|---|---|---|

| Total amount of waste plastic generated | 74,426 | 75,684 | 73,642 | 65,572 | |

| (Amount of recycled paper mixed in as raw material) | (67,696) | (68,984) | (67,449) | (60,978) | |

| Recycled amount (including thermal recycling) | 69,678 [94%] | 73,798 [98%] | 72,419 [98%] | 64,561 [98%] | [100%] |

| (of which material and chemical recycling) | (804) | (763) | (282) | (338) | |

| Unrecycled amount | 4,749 [6%] | 1,886 [2%] | 1,215 [2%] | 1,009 [2%] | [0%] |

| Sales of sustainable packaging | 1,904 | 3,312 | 3,297 | 3,141 | 5,000 or more |

- *4 Includes some non-packaging plastic alternative paper products

3. Details of efforts as a specified plastic product provider

Grand Hotel New Oji, a provider of specified plastic-using products, has set rationalization targets for 12 specified items and is implementing reduction activities, with the aim of contributing to the preservation and sound development of the living environment.