- Policy

- Structure

- Targets and Achievements

- Purification of wastewater

- Purification of exhaust gases

- Initiatives

- Wastewater Treatment Initiatives

- Exhaust Gases Purification Initiatives

- Data

Policy

The Oji Group recognizes that reducing environmental impact caused by pollutants is a material issue that must be addressed as we moves toward the realization of a sustainable society.

To reduce environmental impact caused by pollutants in wastewater and exhaust gases, the Oji Group has set reduction targets for BOD, COD, SS, SOx and NOx under the Environmental Action Program 2030 and/or 2040, and is actively working toward achieving them. We establish voluntary standard values that are stricter than those required by relevant laws and regulations, and ensure legal compliance while preventing pollution. Additionally, we work to prevent pollution through thorough legal compliance measures.

Structure

Targets and Achievements

Purification of wastewater

In the Environmental Action Program 2030, the Oji Group has set a target to reduce the emission intensity of BOD, COD, and SS by 15% or more by FY2030, using FY2018 as the baseline year.

In the Environmental Action Program 2040, formulated in May 2025, the Oji Group has set a target to reduce the total emissions of BOD, COD, and SS by 20% by FY2040, using FY2018 as the baseline year.

- *1 BOD: Biochemical oxygen demand

- *2 COD: Chemical oxygen demand

- *3SS: Suspended solids

- * This table can be viewed by scrolling horizontally.

| FY2018 (Base Year) |

FY2019 | FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | FY2030 (Target) |

||

|---|---|---|---|---|---|---|---|---|---|

| BOD |

Intensity (kg/ million yen) |

5.48 | 5.48 | 5.93 | 5.28 | 3.67 | 3.33 | 3.31 | 4.66 or less |

| Reduction rate | - | 0.1% | 8.3% | -3.6% | -33.1% | -39.2% | -39.7% | -15.0% | |

| COD |

Intensity (kg/ million yen) |

24.86 | 25.52 | 26.77 | 26.58 | 21.91 | 20.91 | 19.03 | 21.12 or less |

| Reduction rate | - | 2.7% | 7.7% | 6.9% | -11.9% | -15.9% | -23.4% | -15.0% | |

| SS |

Intensity (kg/ million yen) |

10.62 | 11.08 | 11.11 | 10.31 | 8.16 | 7.53 | 7.14 | 9.02 or less |

| Reduction rate | - | 4.3% | 4.6% | -2.9% | -23.2% | -29.1% | -32.8% | -15.0% |

Purification of exhaust gases

In the Environmental Action Program 2030, the Oji Group has set a target to reduce the emission intensity of SOx*4 by 15% by FY2030, using FY2018 as the baseline year. In addition, the emission intensity of VOC*5 is targeted to be reduced by 50% or more by FY2030, using FY2010 as the baseline year.

In the Environmental Action Program 2040, formulated in May 2025, the Oji Group has set a target to reduce the total emissions of SOx by 50% and NOx*6 by 10% by FY2040, using FY2018 as the baseline year. Furthermore, the emission intensity of VOC is to be maintained at the FY2018 level.

- *4 SOx: Sulfur oxides

- *5 VOC: Volatile organic compound

- *6 NOx: Nitrogen oxides

- * This table can be viewed by scrolling horizontally.

|

FY2018 (Base Year) |

FY2019 | FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | FY2030 (Target) |

||

|---|---|---|---|---|---|---|---|---|---|

| SOx |

Intensity (kg/ million yen) |

4.12 | 3.78 | 4.07 | 3.69 | 3.49 | 2.98 | 2.90 | 3.50 or less |

| Reduction rate | - | -8.2% | -1.3% | -10.5% | -15.4% | -27.8% | -29.7% | -15.0% | |

| VOC |

Intensity (kg/ million yen) |

0.61 | 0.32 | 0.17 | 0.16 | 0.11 | 0.09 | 0.08 | 0.30 or less |

| Reduction rate | - | -47.5% | -72.1% | -73.8% | -82.0% | -85.2% | -86.9% | -50.0% |

Initiatives

Wastewater Treatment Initiatives

Management of Compliance with Regulatory Values

The Oji Group drains the wastewater generated by its business activities into various waterways after reducing the environmentally hazardous substances in it to below regulatory values through physical, chemical and biological treatment processes.

As part of the wastewater monitoring process, we monitor and manage discharge water quality. We measure the quantity of pollutants in line with laws and control them by continuously measuring the wastewater. If the quantity of a pollutant exceeds our voluntary standard value, we take measures to prevent pollution by suspending operations.

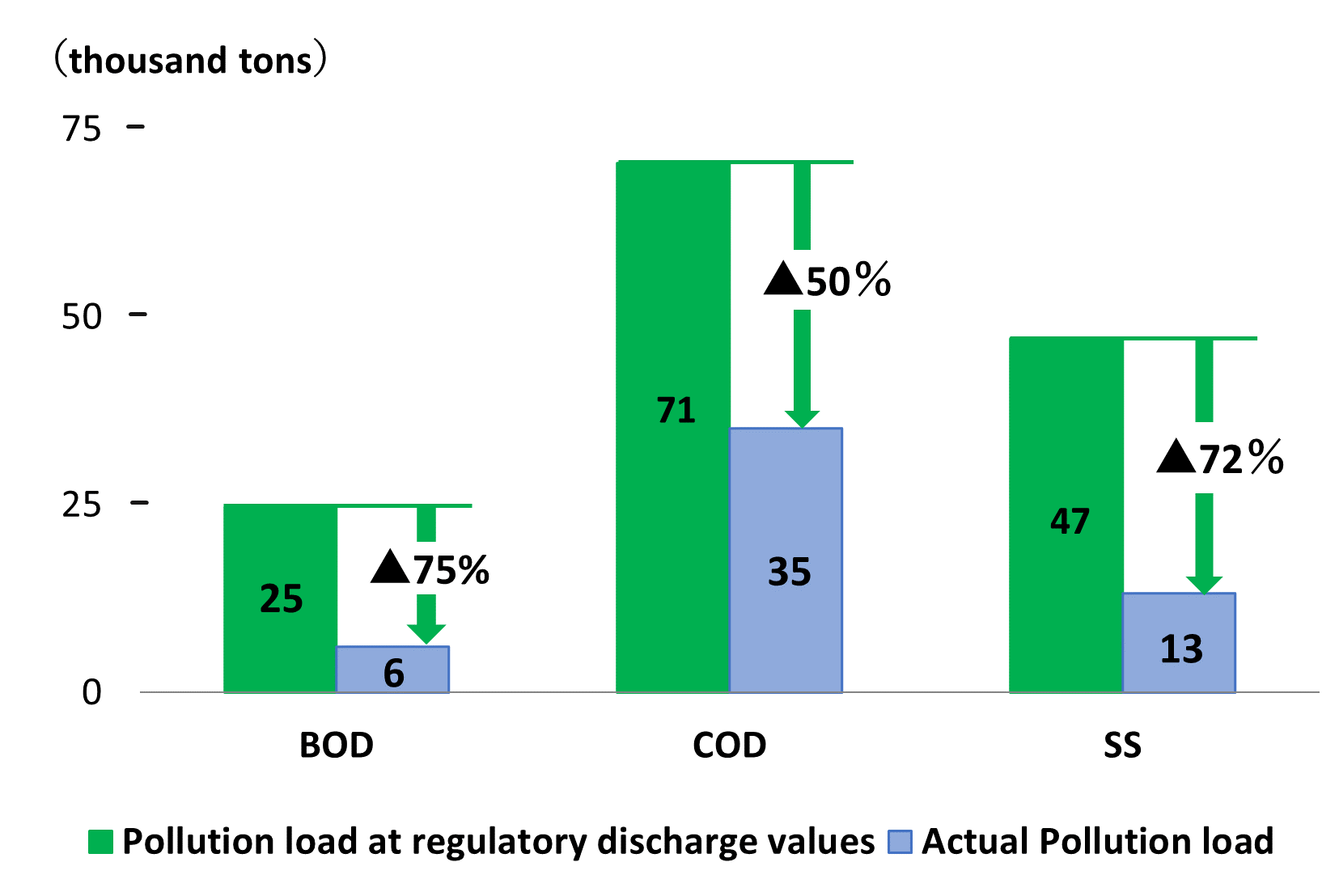

Each Group mill manages wastewater quality using voluntary management values that are stricter than the regulatory values stipulated by laws and ordinances, ensuring compliance with these regulatory values. We are committed to purifying wastewater. For example, in FY2024, we reduced COD (chemical oxygen demand) in wastewater by 50% compared to the emissions that would have been allowed under the regulations.

Pollution load in wastewater(BOD, COD and SS)*7 (FY2024)

- *7 BOD (Biochemical oxygen demand)

Biochemical oxygen demand (BOD) represents the amount of oxygen consumed by microorganisms to decompose organic matter under aerobic conditions. When BOD is elevated, foul odors, etc. are produced.

COD (Chemical oxygen demand)

Chemical Oxygen Demand (COD) represents the amount of oxygen required to chemically oxidize organic materials.

SS (Suspended solids)

Particulates suspended in water.

Reduction of Pollutants in Wastewater

To ensure that wastewater discharges remain below voluntary standard values that are stricter than regulatory Values, the Oji Group installs and operates dedicated wastewater treatment plants. Specific initiatives are outlined below.

Oji Paper and Oji Materia (Japan)

At each mill of Oji Paper and Oji Materia, wastewater purification is carried out through tertiary treatment as recommended in the Best Available Techniques (BAT) for the pulp and paper industry (BAT 7.3.12). In addition to this advanced treatment, voluntary standard values that are even stricter than regulatory values are set to further enhance purification efforts.

For technical details, please refer to the Best Available Techniques (BAT) Reference Document for the Production of Pulp, Paper and Board(europa.eu).

IPI (Italy)

In 2023, IPI replaced ion exchange resins with RO membrane treatment equipment for the softening of hard water used in production processes. This change has contributed to the purification of wastewater by reducing the generation of chloride ions.

Furthermore, to improve and stabilize the quality of treated water and optimize operational costs and management, the Group has begun developing advanced wastewater treatment technologies utilizing remote monitoring and AI.

In FY2024, total expenses and investments related to wastewater treatment and other water-related activities amounted to 7,796 million yen and 1,076 million yen, respectively.

Exhaust Gases Purification Initiatives

Reduction of Chemical Substances Emissions in Exhaust

Management and Monitoring Processes for Compliance with Regulatory Values

The Oji Group owns several boilers and turbines. The electricity and thermal energy obtained through the direct combustion of fossil fuels, waste fuels and renewable fuels are used internally and provided to local communities.

The Group has set voluntary standard values that are stricter than the regulatory values regarding the atmospheric release of the pollutants produced through direct combustion. When measured values exceed these voluntary standard values, we suspend operations and take other measures to prevent pollution.

As part of our monitoring efforts, the Oji Group has adopted a Continuous Emissions Monitoring System (CEMS) for SOx, NOx, and dust to ensure compliance with laws and regulations. In addition, major mills continuously transmit measurement data to regulatory authorities via online systems. Alongside continuous monitoring, third-party certified measurement providers regularly conduct independent analyses to verify emission levels.

Status of Reduction of Chemical Substances in Exhaust

To ensure that emissions of air pollutants remain below voluntary standard values that are stricter than regulatory values, the Oji Group installs and operates air pollution control equipment such as desulfurization equipment, denitrification equipment, cyclones, scrubbers, and bag filters.

Under the guidance of the Japan Paper Association, the Oji Group has set VOC reduction targets in the Environmental Action Programs 2030 and 2040, and is actively working to achieve them.